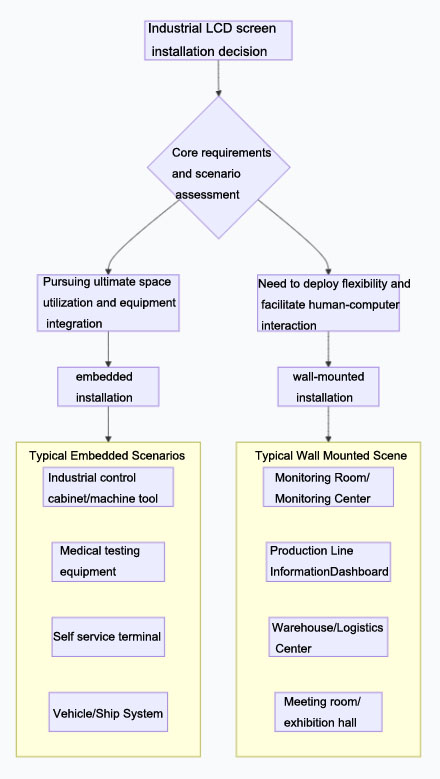

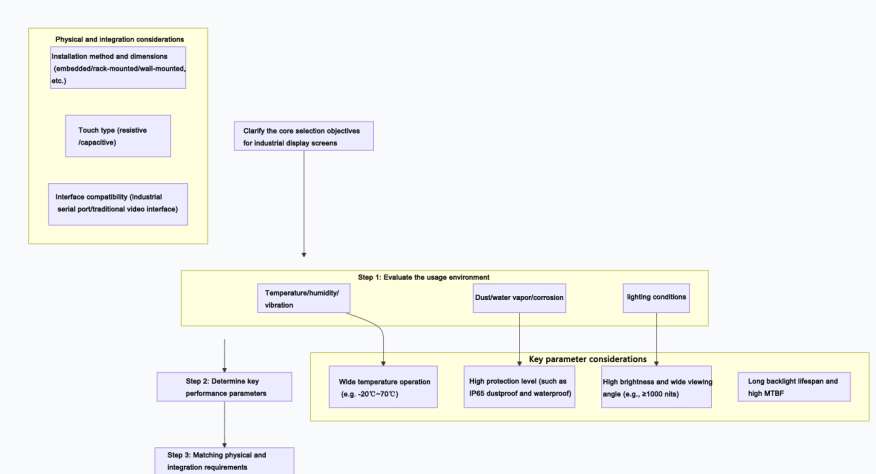

How to choose the installation method of industrial LCD screen: embedded install

The core difference between embedded and wall mounted installation of industrial LCD screens lies in "fixed integration " and "flexible deployment " The choice of method mainly depends on your space, environment, interaction, and maintenance needs