Comparison between TFT LCD screen full lamination technology and frame laminatio

Before introducing the bonding technology of TFT LCD screens, we first need to understand the basic structur

Comparison between TFT LCD screen full lamination technology and frame lamination technology

Before introducing the bonding technology of TFT LCD screens, we first need to understand the basic structure of LCD screens. LCD screens with touch function can be divided into three parts: outer glass cover, capacitive touch module, and TFT LCD screen. The process of integrating and bonding these three elements together is called LCD screen bonding technology. So LCD screens with capacitive touch generally need to be bonded twice, first between the outer glass cover and the capacitive touch module, and then between the touch module and the TFT LCD screen. There are many types of bonding technologies for TFT LCD screens, and the two most commonly used are full bonding technology and frame bonding technology for TFT LCD screens.

What are the definitions of full lamination technology and frame lamination technology for TFT LCD screens?

Full lamination technology: a technical process that uses optical adhesive to seamlessly bond the glass cover, touch module, and display screen together. The adhesive used for bonding is generally divided into two types. OCA optical adhesive is generally used for small and medium-sized LCD screens, while LOCA water-based adhesive is commonly used for large-sized LCD screen devices. Full lamination technology, also known as optical lamination technology, can eliminate gaps between glass and improve the overall stability of the screen.

Frame pasting technology: Frame pasting technology, also known as mouth glue bonding technology, uses double-sided tape to fix the four edges of the screen, bonding the glass cover, touch module, and display screen together. The cost of frame pasting technology is relatively lower. However, it is inferior to full lamination technology in terms of stability and tactile feel.

Who has the advantage over TFT LCD screen full lamination technology and frame lamination technology? Compared to frame bonding technology, full lamination technology for TFT LCD screens has many advantages in many aspects.

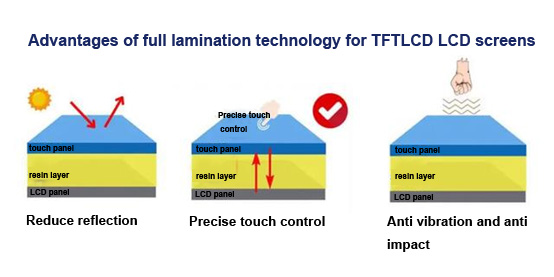

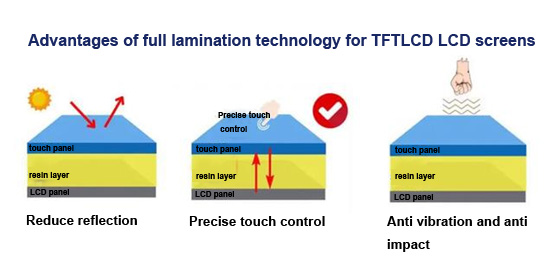

1.Improved clarity: Due to optical bonding eliminating gaps between each other, internal reflections between the glass cover, touch module, and display screen caused by ambient light are reduced, improving the overall contrast and optical properties of the display screen, thereby making the screen image clearer and brighter.

2. Dustproof and waterproof: The fully bonded technology has better sealing, preventing water vapor from entering the screen gap and eliminating the possibility of screen fogging and condensation. At the same time, it also resists the entry of stains and dust, keeping the inside of the screen clean and extending its service life.

3. Improved touch sensitivity: The full lamination process makes the touch screen more sensitive and provides a better touch experience.

4. Stability improvement: The fully bonded screen is more sturdy and has stronger defense against external impacts and vibrations, enhancing the overall stability of the screen.

The advantages of full lamination technology for TFT LCD screens

Although frame pasting technology lags behind full lamination technology in many aspects, it also has its own advantages. 1. Low cost: Full lamination technology requires machine lamination and also has certain requirements for equipment accuracy, while frame lamination technology mostly relies on manual lamination. Therefore, the cost of frame pasting in terms of consumables, processes, etc. is relatively lower. 2. easier maintenance in the later stage: Due to the use of double-sided tape with four sides for frame pasting, the disassembly and reassembly methods are relatively simple, which is more conducive to later maintenance and repair. In summary, TFT LCD screen full lamination technology and frame lamination technology each have their own advantages. For devices that require higher display quality and touch accuracy, full lamination technology is undoubtedly more advantageous. For products with stricter cost control or no touch requirements, frame pasting technology is more suitable. Of course, there are also more compromise options to choose from. For example, full lamination technology is used between the cover glass and the touch module, while frame lamination technology is used between the touch module and the display screen. While ensuring touch accuracy, it also controls product costs. IDT Technology supports this type of bonding solution. We have optimized the frame pasting technology by using L-shaped and Z-shaped adhesive ports, which have achieved good dust and water vapor resistance effects. Please refer to the following picture for details. Feel free to consult.