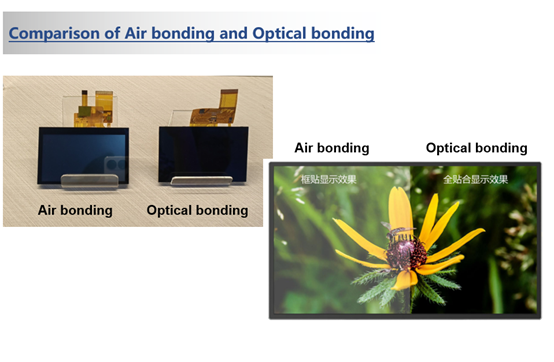

Unique advantages of optical bonding

Optical bonding supports the use of OCA thick adhesive bonding technology, using Lucent Gel optical adhesive with

Optical bonding supports the use of OCA thick adhesive bonding technology, using Lucent Gel optical adhesive with a thickness ranging from 0.2mm to 1.8mm, suitable for different types of LCD panels, including: iron framed LCD panels, ironless (encapsulated) LCD panels, Open Cell displays, etc. AMT currently supports optical bonding from small-sized to 32 inch LCD panels. We have accumulated a lot of experience in optical bonding, which can overcome the limitations of different LCD panels and provide industry-leading optical bonding technology. AMT optical bonding support type:

- Touch panel, cover glass, plastic shell

- Flat fitting, irregular fitting, curved fitting

- Bezel LCD、Cell Tape LCD、Open Cell、OLED、EPD

EPaper optical bonding

With the global attention to environmental protection and energy conservation, the demand for electronic paper (ePaper or EPD) is booming in the market, and the optical bonding technology of ePaper is also highly valued. The biggest challenge in the optical bonding of EPD and cholesterol liquid crystal (Ch LCD) is that the bottom glass is relatively thin. If the bonding pressure is too high or uneven during the process, it will cause the glass to break; If water glue bonding is used, there is a possibility of glue overflow, and the curing shrinkage of water glue can easily cause Mura problems.

IDT optical bonding uses solid-state optical adhesive made of silicone. The vacuum bonding pressure and defoaming pressure are low, and when combined with our self-developed bonding fixture, it can avoid problems such as excessive and uneven bonding pressure, as well as the occurrence of stress Mura. We can attach glass cover plates to the surface of EPD/Ch-LCD to protect the product from damage; It can also assist in adding a front light panel on the EPD, so that the screen content can be clearly seen in low light environments; We can also incorporate UV resistant design into the structure to avoid LCD yellowing or cracking.

The unique bonding technology

IDT Not only can we provide optical bonding between the touch panel and LCD panel, but considering that some customers' applications do not require touch functionality, but they hope to attach a glass cover to the LCD panel to protect it, and require some special surface treatment or added value functions on the glass cover, we are happy to serve our customers. AMT optical bonding is an optical adhesive made of silicone material, which has excellent weather resistance and impact resistance, and can improve the reliability of LCD panels, meeting a wide range of application needs such as industrial, medical, automotive, or outdoor products.

Some LCD panels on the market tend to have narrow bezel designs. When the bezel of the LCD panel is very narrow and thick optical adhesive is used, after optical bonding, a bright edge may be seen at the edge of the LCD action area when the LCD panel is tilted. AMT uses special manufacturing processes and optical bonding technology to prevent bright edges from being visible when viewed from a diagonal angle on LCD panels.

Some new products use curved screens (such as car dashboards or gaming devices) to provide a novel and eye-catching appearance design. In the application system of rail transit, a dual screen design will be adopted, which means there will be two displays on one piece of glass, with the intention of providing backup immediately when one of the screens fails. AMT's excellent optical bonding technology can support the bonding of curved displays or dual screens.

Product Features

Using Lucent Gel solid-state optical adhesive

No curing process required, less prone to stress Mura

Low pressure for adhesion and defoaming, suitable for displays that are not resistant to high pressure (such as: OLED、EPD、Open Cell)

Suitable for 3D (2D bonding surface, 3D appearance) or multi-mode bonding of plastic parts, optimizing production capacity