What are the optical bonding characteristics of touch screens?

There are two bonding methods for touch panels and LCDs, namely double-sided adhesive bonding (frame bonding) and optical bonding (full bonding) Frame pasting is done using double-sided adhesive tape with a mouth shape

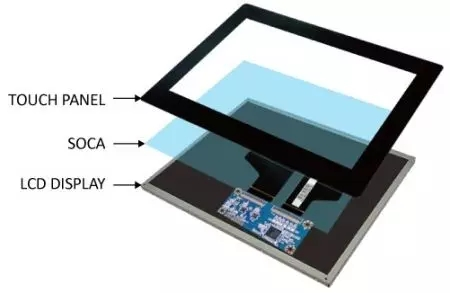

There are two bonding methods for touch panels and LCDs, namely double-sided adhesive bonding (frame bonding) and optical bonding (full bonding). Frame pasting is done using double-sided adhesive tape with a mouth shape, while optical pasting is done using optical adhesive that covers the entire display area. Many products today require the use of optical bonding, which uses liquid glue (OCR) or solid glue (OCA) to fully bond the touch panel and LCD, eliminating any air layer between the touch panel and LCD to enhance panel durability and optical properties, and reduce parallax.

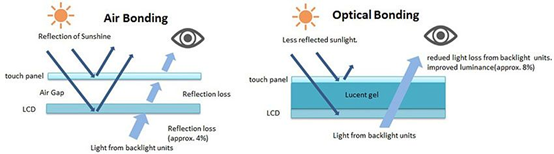

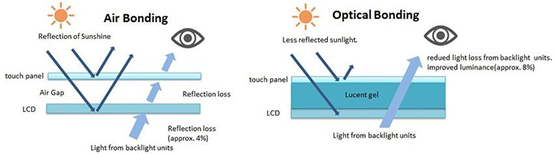

The main difference between double-sided adhesive bonding and optical bonding lies in whether there is an air layer between the touch panel and LCD. When there is an air layer between the touch panel and LCD, the difference in refractive index will cause the reflectivity of light to increase and the transmittance to decrease, while also making the display screen appear less clear and vivid. Optical bonding can fully bond the touch panel and LCD panel, eliminating any air layer between the touch panel and LCD, reducing parallax, lowering external light reflection, and improving backlight penetration, providing excellent clarity and durability for LCD touch modules.

Product Features

• Improve optical performance

• Reduce reflectivity

• Improve LCD light transmittance

• Reduce disparity

• Shock absorption

• Avoid condensation of water vapor

• High reliability

touch screens:https://www.idtdisplay.com/products/industrial_touch_screen/